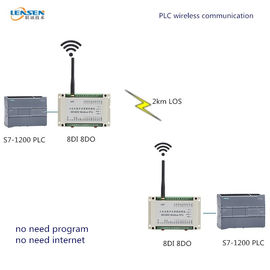

UHF Wireless I/O Module 8DI 8DO Wireless PLC 2km ON-OFF control

1. LS-RDIO0808 general introduction

This is a 8DI8DO wireless RTU

It has 8 digital input, 8 relay output

There is a 1W RF module inside, it's OK to control 2km

2. Application Field

LS-RDIO series I/O module is widely used in industry automation like factory central data process, pump control, oil monitoring, mining machinery, environment monitoring equipments, lifting devices, robots control, filling machine, mixing equipments, logistic line, AGV etc.

Conveyor Control

Control a conveyor motor remotely

Remote Control Relay

Use dry contact inputs to control a remote relay.

Problem Notification

Save time in large facilities by activating an overhead notification light when a problem occurs, letting the supervisor know exactly where to go.

Dust Suppression

Use wireless I/O module to operate your dust

Data Logging

Wirelessly acquire and log various data from a remote location using our analog I/O module

Stacker Control

Start and stop your stacker/reclaimir. Connect PLC in control center with stacker and reclaimer.

Proximity Detection

Mount a transmitter with adjustable range on heavy equipment, mount a receiver in a “blind spot,” and then set up the receiver to sound an alarm or turn on a light whenever the equipment is operating in the area.

Chemical Level Monitoring

Monitor water chlorination or other chemicals remotely.

Traffic Signals

Avoid having to lay new wire by using wireless transmitters and receivers to control traffic signs such as “Railroad Crossing Ahead” when a train is present.

Grain Elevators

Our wireless transmitters and receivers can be used to monitor grain elevator conditions or control different functions. To collect RS485 data. To monitor temperature and humidity in Grain.

Freight Loading

Digital I/O module for crane control and analog I/O module to send the load information wirelessly to another location.

3. Parameter

| Parameter |

| Power output: |

1W or 100mW version |

| Power supply: |

9V-30V (usually choose 24V DC or 12V DC) |

| Control distance: |

3km or (1km version) |

| Baud rate: |

1200bps |

| Receiving sensibility: |

-123dBm@1200bps, -118dbm(9600bps) |

| Networking |

| Networking: |

Point to point and point to multipoint |

| Port Description |

| Input: |

8 active DI (passive customized) |

| Output: |

8 relay passive outputs,

contact max load AC250V/5A,DC30V/5A

(Active output 0-5V customized)

|

| Communication port |

RS485 (wireless RS485 customize) |

| Current |

| Transmit current: |

<600mA (or 100mA version) |

| Receiving current: |

<50mA (or 20mA version) |

| General |

| Frequency: |

433MHz, 400, 450, 470 or other band |

| Channel No: |

16 channels,can change via DIP switch |

| Physical Properties |

| Dimension: |

145×90×40(mm) |

| Antenna Connector: |

SMA,vehicle antenna with 1.5m cable |

| Temperature: |

-35℃~+75℃( industrial) |

| Mounting method: |

Standard 3.5 inch industrial guild rail |

4. How to use wireless I/O

5. Application diagram examples

One master to 8 salves

Remarks:

| Master |

Salve |

Input and control correspondence |

| A(DI1) |

B1(DO1) |

DI1 of A control DO1 of B1 |

| A(DI2) |

B2(DO1) |

DI2 of A control DO1 of B2 |

| A(DI3) |

B3(DO1) |

DI3 of A control DO1 of B3 |

| A(DI4) |

B4(DO1) |

DI4of A control DO1 of B4 |

| A(DI5) |

B5(DO1) |

DI5 of A control DO1 of B5 |

| A(DI6) |

B6(DO1) |

DI6 of A control DO1 of B6 |

| A(DI7) |

B7(DO1) |

DI7 of A control DO1 of B7 |

| A(DI8) |

B8(DO1) |

DI8 of A control DO1 of B8 |

| A(DO1) |

B1(DI1) |

DO1 of A is controlled by DI1 of B1 |

| A(DO8) |

B8(DI1) |

DO8 of A is controlled by DI1 of B8 |

| Note: module A and B should use the same channel; |

To communicate with PC/PLC

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!